IBC: formwork and reinforcement planning and design to the power of 3

In response to an increasing demand for element-oriented design, IBC Ingenieurbau-Consult GmbH recently made the change to the BIM-capable CAD Strakon software von Dicad. The Managing Directors of Engineering report on experience gained in changing from 2D to 3D Planning in structural design.

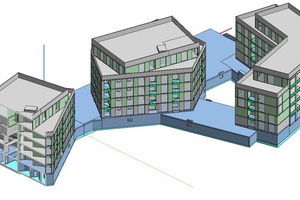

Key activities of IBC Ingenieurbau-Consult GmbH from Mainz in Germany, established already in 1964, are the design of structural systems and façades, building physics, project supervision, client consultation, checking and preparation of expert opinions. The IBC team of 85 accompanies projects in all performance phases – from basic analysis to design and approval phases to site supervision. The project spectrum comprises office, administrative and residential building as well as specialized structures such as theaters, congress centers, laboratory building , selling points and television studios.

“Clients expect 3D and BIM”

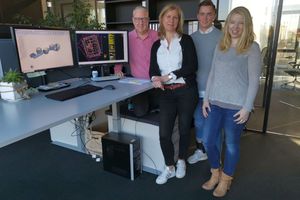

In order to automate processes and data transfers and to comply with the current state of the art, this engineering office recently changed from 2D software to the 3D and BIM-capable CAD software for structural design – Strakon from Dicad. Responsible for the change in software, which at the same time is also an entry into a new work method, were Susanne Jäck and Thorsten Karg, both Managing Directors in the Engineering Business Unit.

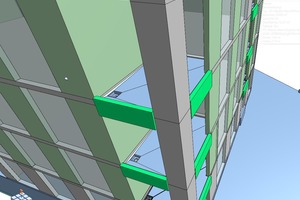

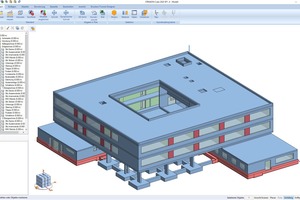

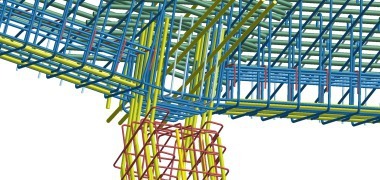

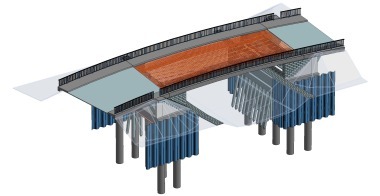

Karg names additional reasons for the change: “3D und BIM are increasingly more frequently specified by the contractor as a prerequisite for participating in projects. For that reason – and in order to further expand our competitive edges – we decided on the change. Increasingly more complex project planning and our striving for cost-efficient solutions are placing increasingly higher requirements on structural design – and on our tools. In this context, 3D CAD helps us prevent design errors and recognize collisions early. In addition, this facilitates exchange among all parties involved in formwork and reinforcement planning and structural design efforts: and last but not least, 3D supports us in entering the BIM design method and participating in openBIM projects,” adds Susanne Jäck.

Reasons for Strakon

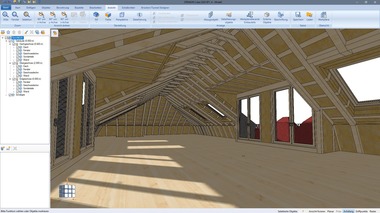

Because the existing CAD program no longer met the increasing demands and requirements placed on model-oriented design, the choice was made after careful evaluation of the market in favor of Strakon from Dicad. “Strakon convinced us because it is tailored to in-situ concrete and precast construction, and because it is flexible and easy to operate,” as Thorsten Karg explained the reason for the decision. He continues: “We had been aware of Strakon as a very good 2D program for some time. Now we are making use of its strengths in the 3D sector and for in-situ concrete construction.”

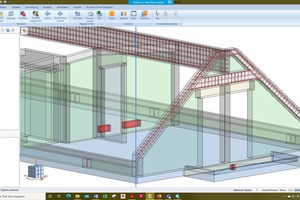

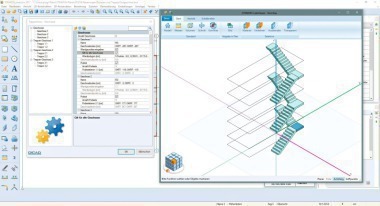

Additional reasons for the decisions were the little effort required for changing from the old to the new program and flexible 2D/3D processing that leaves users with great freedom when alternating between 2D- and 3D-oriented work. Numerous functions such as automatic 3D reinforcement, fast modeling and optional 3D staircase modules enable efficient planning of in-situ concrete and formwork. Susanne Jäck and Thorsten Karg also positively assess Dicad’s corporate philosophy that includes Strakon users in further development and optimization of the program. In working groups and in regional meetings of users they can, moreover, mutually exchange experience in the application and further development of the program.

Change as opportunity and challenge

That the change did not take place smoothly lies in the nature of things. “More senior staff, in particular, had difficulties in adjusting to the new program. The customary drawing-oriented work method practiced for many years was suddenly considered outdated. Staff of many years’ standing had to familiarize themselves with new functions. While some of the younger staff already had prior knowledge of the new method and were motivated, older staff still needed to be convinced of its advantages,” recalls Karg. In the end, everybody was able learn from each other: older staff could pass on their experience and received in return tips on 3D design from younger staff. That familiarization with the new program had to take place in daily operations presented an additional challenge. Jäck is convinced that without the dedication and commitment of the staff and the support from Dicad it would not have been possible: “An individual Strakon course and last but not least the hotline service helped us overcome initial problems. As soon as questions arose, we obtained fast and easily understood advice and help from remote servicing.”

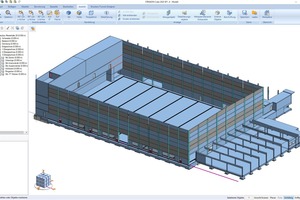

Staff was trained partly by Dicad and partly in-company. Already trained staff were able to train other staff. The rest was learning by doing. One staff member was in charge of technical details and had made changes to the company-specific program settings and individualized, for example, design submission, stamps and symbols. Simultaneously, a test project was started on which the staff could gain and exchange experience. By now, residential and hall projects are being planned for in-situ concrete construction on a total of seven workstations. An additional four workstations for precast projects will be added.

More quality in planning and design, fewer errors

The change was worthwhile. The quality in planning and design, for example, was able to be further enhanced, Jäck was pleased to note: “Based on the 3D models, design errors are noticed earlier and changes to the ground plan, the views and the sections are made automatically. The dimensions and the reinforcement adjust automatically as soon as the geometry changes. Another aspect is the increase in activity on workstations and in the company as well greater motivation of the staff. With 3D visualization, we are able to present construction projects more vividly to the clients and project participants. Conflicts and problems are recognized already during planning and not later at the construction site.”

But Karg also knows the challenges: “Many architects and specialized consultants do not submit clean 3D models and sometimes mix 2D elements and 3D construction components in a project. The quality of the IFC data is accordingly inadequate. When, in addition, information is lost during IFC data transfer, the 3D building model becomes practically unusable. Building services are sometimes completely missing, with the result that cable and pipe routing, blockouts and openings in walls cannot be adequately considered.” Actual practice, in his view, at present has a long way to go to achieve an openBIM process across disciplines and trades. Internal workflow is in need of optimization: more specifically, this involves structural design, calculation, reinforcement and feedback with architects and specialized consultants – in particular with regard to agreements, communication and data transfer. But notwithstanding all this, the medium-term objective of BC Ingenieurbau-Consult is the realization of openBIM; i.e., interdisciplinary cooperation on a digital building model with various software solutions and project partners.

Admission ticket to the BIM world

On the basis of their experience, Jäck and Karg also have tips for the change from 2D to 3D and BIM. Karg recommends proceeding with caution: “First of all, one should take sufficient time and not rush into a decision – because the program should fit the company’s needs. The entire staff – most of all, senior staff – should be included early on, motivated and convinced of the new working method.” Jäck adds: “It is also important to proceed step-by-step and group-by-group so that no one is overtaxed and day-to-day business can continue in parallel. Young staff should be won over as comrades in arm, since they usually have a positive attitude toward new working methods and can motivate others.”

“The time of the change is also important –change should especially not take place in the middle of a project,” cautions Karg. The retrospective conclusion of both is unanimously positive. Jäck sums up: “3D has brought us further – for us, it is the admission ticket to the world of BIM. The strategic goal of our change is introduction of the BIM design method and participation in openBIM projects.”