Röckelein modernizes with latest mixing technology of Eirich

The world of gardening and landscape construction is the most important pillar of Baustoffwerk Altendorf K. Röckelein GmbH & Co KG. Modern and classic paving blocks in fanciful shapes, colors and sizes can be found here. For ensuring the highest level of artistic freedom in designing the decorative elements, Röckelein has been relying on the quality and reliability of Eirich mixing technology for decades now. The latest generation of the successful R12 series was presented at the last Bauma in 2019. At the end of the trade show days, the face concrete mixer traveled to the district of Bamberg in Upper Franconia.

A successful family-run company looks ahead

Wolfgang Röckelein is managing the company founded in 1946 in the second generation. With foresight, he decided together with his son and successor, Christoph Röckelein, to modernize the existing production line in Altendorf. Having as much flexibility as possible in terms of capacity was an essential criterion here, apart from the technical renewal. The decision was taken in favor of the RV12 model of Maschinenfabrik Gustav Eirich GmbH & Co KG, providing a maximum capacity of 500 l but also allowing processing of minor volumes of up to 150 l. This facilitates product changes and increases the flexibility, in particular, when colored face-mix concrete is concerned.

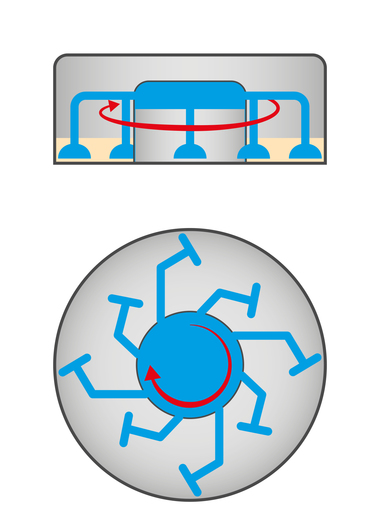

In respect of model updating of the RV12 500, Eirich did not accept any compromise. The now already third facelift was regarded in detail and was optimized in terms of user-friendliness. Among other things, they provided for much better accessability for cleaning and maintenance. The overall outcome was the most modern face concrete mixer ever manufactured by Eirich, according to their own statement. Thus, short mixing times are combined with perfect homogeneity, for example, so as to reproduce the complicated color shades of natural stones. New shapes and surfaces can be developed for any imaginable field of application. Color pigments are to be disintegrated in an optimum way. This requires that the mixing plant, color dosing system, block machine and material handling equipment are perfectly coordinated with each other.

The Eirich D23 provides for the core of the paving block

Core concrete provides for stability and a long service life of paving blocks, masonry bricks, curbstones and border stones. A stable block allows for freedom of design and is guarantor of an elegant design language. For this purpose, Eirich presented the mixer type D23 at Bauma 2016. With effective capacities of 1500 l to 3000 l, this mixer generation is suitable for a lot of fields of application. Therefore, Röckelein decided in favor of Eirich when choosing the core concrete mixer.

Röckelein – environmental protection & sustainability through innovation

Environmental protection takes top priority for Christoph Röckelein in day-to-day actions. A significant contribution is made to environmental protection by selecting environmentally friendly building materials and the renaturalization of quarry ponds right up to the use of fuel-efficient vehicles.

As regards production and manufacturer, Röckelein relies on the experience of the machine manufacturing company based in the Odenwald region. The hybrid mixing process is operating with lowest possible energy consumption and wear. This, completed by a rugged design, allows for a very long service life at low maintenance requirements. Energy-efficient high torque motors ensure energy and CO2 savings, thus actively contributing to climate protection. The high quality of the individual batches results in less waste, what in turn leads to a higher resource efficiency. On the whole, such investments already pay off after a short operating time.

Apart from the mixing technology, Eirich provided for a smooth replacement and the recommissioning of both mixers. After the successful installation, the production of concrete blocks could be continued in Altendorf with state-of-the-art technology. Along with the mixing technology, Röckelein has invested in a completely new paving block manufacturing line. This is to secure the competitiveness of the company for the generations to come.

CONTACT

Maschinenfabrik Gustav Eirich GmbH & Co. KG

Walldürner Str. 50

74736 Hardheim/Germany

+49 6283 510