Dual studies against the shortage of skilled workers

Abstract:

The Nuremberg University of Applied Sciences has recently started offering dual study models for ceramic engineers in the Faculty of Materials Engineering, which enable companies to actively combat the shortage of skilled workers. These study models for both the Bachelor's and Master's degree programmes are described below, along with the prerequisites that interested parties and companies must bring with them.

In addition to the enormous increase in energy costs, the shortage of skilled workers is one of the dominant issues in the ceramics industry. Many companies are desperately looking for suitable junior staff, also in the academic field of ceramic engineers.

At the Nuremberg University of Applied Sciences Georg-Simon-Ohm (THN), the Faculty of Materials Engineering (WT) has been training materials engineers for 50 years. One focus has always been on the specialist areas of ceramics and glass. A significant proportion of the ceramics engineers employed in Germany graduated from the TH Nuremberg.

The 7-semester Bachelor‘s programme now bears the title „Applied Materials Science“. Until 2010, the programme exclusively taught non-metallic-inorganic materials (NAW), i.e. glass, ceramics and binding materials. Since then, the subject matter has been opened up to all material groups, which was absolutely necessary in order to stabilise student numbers. Nevertheless, the subject matter in the specialist areas of glass and ceramics was not reduced. On the contrary. After a basic course of study, which comprises the first three semesters and covers the classical engineering basic training as well as basic lectures of all material groups, i.e. also metals and plastics, the students choose special focal points from the 4th semester onwards. In the field of NAW materials, these are silicate and coarse ceramics, high-performance and functional ceramics, glass, binders, nanomaterials, composites and electrical engineering materials.

In the field of „heavy clay ceramics“, students are taught relevant knowledge about the production and material-technical properties of heavy clay products such as roof and wall tiles. All process engineering steps, starting from clay mining, the chemical-mineralogical composition of clays and aggregates, preparation, shaping, drying and firing, packaging, quality control, porosification agents, glazes up to the brick properties are examined. In addition to the above-mentioned focal points, the study programme also covers all essential peripheral areas such as surface technology, electronics, medical technology, energy technology, mechanical engineering, etc. In addition, contents that are important for industry today are taught, such as quality management, business administration, finite element simulation, construction, statistics (DoE, SixSigma). There are corresponding practical courses for almost every teaching module (see Figs. 1-3).

A 3-semester Master‘s programme „New Materials, Nano and Production Technology“ builds on the Bachelor‘s programme, in which students can again choose their focus from the 3 subject areas NAW materials, metals or plastics, where they receive an intensive deepening of their materials science knowledge.

The industry frequently expressed the wish to offer dual study models that enable companies to establish a bond with students at an early stage and thus generate new talent in a targeted manner, or to enable employees to study and thus receive further professional training (e. g. „study with in-depth practice“) without losing the employees to the university for years. In response to this wish, the Faculty of Materials Engineering has recently started offering interesting dual study models, which have already been very well received by various companies.

A distinction must be made here between what is classically understood as dual study, namely a combination of apprenticeship and study, and a model that is becoming increasingly popular, namely study with in-depth practice (without apprenticeship). The different models will be explained below.

Models for the Bachelor‘s degree programme „Applied Materials Science“

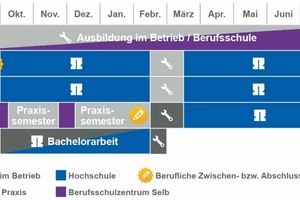

The classic model with a combination of apprenticeship and study is called „composite study“. Different apprenticeships come into question here, such as training as an industrial ceramist or also as a materials tester. Both apprenticeships are located at the vocational school in Selb. Figure 4 shows the schematic structure. After one year of training in the company and at the vocational school, the Bachelor‘s degree programme in „Applied Materials Science“ begins at the TH Nuremberg. The examinations at the vocational school are coordinated with the studies in such a way that they fall during the semester break or the practical study semester (see orange symbols in Figure 4). During the lecture-free period (semester break, marked in grey in Figure 4), students work in the company, as well as during the practical semester and the last semester in which they write their final thesis. This ensures that the student spends very large parts of the study time in the industrial company and is thus prepared in the best possible way for the work in the company.

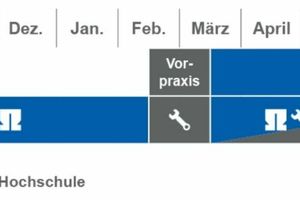

In addition to the classic combined study programme, the „study programme with in-depth practice“ is very popular. There is no parallel training in an apprenticeship, but the student starts studying immediately, but spends all practical phases and semester breaks in the company. This also offers companies the advantage that they can maintain close contact with the student throughout their studies without „losing“ him/her to the university for several years. Meanwhile, about 2/3 of all dual students study in the model „study with in-depth practice“. Figure 5 illustrates this model.

Models for the Master‘s programme

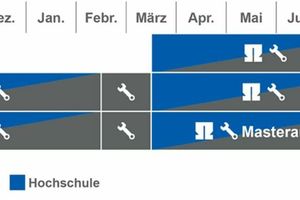

Due to the great demand, Master‘s study models are now also offered. These can either be directly connected to a (dual) Bachelor‘s study model or carried out as continuing education studies. The prerequisite for this is a completed relevant bachelor‘s degree of at least 7 semesters, i. e. a bachelor‘s degree in the field of materials engineering, materials science or related subject areas such as plastics engineering, nanotechnology, metal technology and the like. In the Master‘s programme, only study models of the type „study with in-depth practice“ are offered. Figures 6 and 7 show two possible models. Figure 6 shows the Master‘s programme with in-depth practice as a full-time programme in three semesters. Here, as in the Bachelor‘s programme, working in a company during the semester break and writing the Master‘s thesis in an industrial company are fixed components of the model. Figure 7 shows the part-time model, which is very much in demand, especially in the Master‘s programme. During the Master‘s programme, earning money is often more in the foreground for many students. For this reason, the theory semesters are stretched from 2 to 4 semesters, with only half the number of lectures having to be attended in each semester, leaving more time for working in the company. As a rule, several days per week are then completely free. Incidentally, the Master‘s programme can be started either at the beginning of the summer semester on 15 March or at the beginning of the winter semester on 1 October (without illustration).

Requirements

Prospective students need a university entrance qualification to take up a dual Bachelor‘s programme. This can be the general Abitur, the Fachhochschulreife or a degree from a Fachoberschule (FOS) or Berufsoberschule (BOS) or a comparable qualification. Under certain conditions, it is also possible to study without a (Fach-)Abitur. In this case, separate counselling is absolutely necessary.

If a company would like to become a dual partner company of the TH Nuremberg, a one-time registration at the TH is required. Currently, about 20 companies are already taking advantage of this offer from the Faculty of Materials Engineering. A dual partner company must also be able to have the dual students supervised in their own company by persons with a relevant academic degree. It is also desirable to provide a scientific, company-related topic for the Bachelor‘s or Master‘s thesis in coordination with the THN, which the dual student can work on. If the combined study programme is chosen, the training authorisation for the intended training occupation must also be available.

Companies now have the opportunity to offer selected employees the chance to study while at the same time maintaining company loyalty in order to secure skilled workers. However, there is also the possibility of specifically looking for new employees through a dual study model. Often the demand for this is very high.

The Faculty of Materials Engineering is happy to advise companies as well as prospective students who have questions about the dual study models.