Votorantim Cimentos achieves multi-site digitalization with ABB industry-specific solutions

ABB has delivered advanced automation and digital technologies to global building materials and sustainable solutions company Votorantim Cimentos, as it embraces Industry 4.0 in cement to simultaneously optimize production and decarbonize operations.

Industrial companies, including Votorantim Cimentos Europe, Asia and Africa Region (VCEAA), which has the worldwide capacity to produce 55.7 million t of cement per annum, are ramping up their efforts to ensure lower emissions as governments and international organizations push for net-zero emissions by 2030.

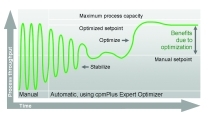

Digital solutions ABB Ability™ Expert Optimizer and ABB Ability™ Knowledge Manager have recently been installed in the customer’s plants in Spain, Turkey, Tunisia and Morocco with proven impacts for enhanced productivity, streamlined processes, reduced maintenance and energy savings. Expert Optimizer, deployed in Votorantim plants since the 1990s, ensures optimization of the complete process and reduces emissions significantly while Knowledge Manager helps in standardizing and ensuring consistency in collecting and analyzing laboratory data across the plants.

Expert Optimizer will minimize energy costs while maximizing the use of alternative fuels and at the same time maintaining and improving the quality of the product. Working closely with Votorantim in engineering and project management, ABB has also provided the Expert Optimizer RMP module to the raw mix to enhance the quality of raw material products going to the kiln. Regarding cement, discrete lab data is combined with continuous process data to optimize production while maintaining cement quality.

ABB has the expertise to ensure higher efficiency in the cement industry using tailored processes and laboratory reporting products. The variability of the feed and fuel will be optimized with the main aim to save money for the plant. During all this, the emissions will be controlled and reduced making the process more environmentally friendly.